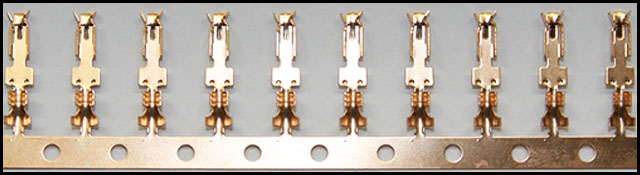

| Product Description: | This vanity mirror bulb socket terminal is used within an automotive application. |

An automotive industry customer approached us to manufacture the vanity mirror bulb socket terminal shown here. Once the die was designed and built, a first article inspection report was submitted to the customer for approval. Due to the high annual volume of parts, this die was built with carbide inserts for both cutting and forming stations. This helps maintain die life. The part is composed of .016” thick CA521 phosphor bronze, and required tolerances of ±.003”. Manufacturing was performed on our high speed 4 post 30 ton Bruderer press. In order to meet the customer’s automatic assembly requirements, the parts were run on a reel-to-reel format. This feature also allows for automatic packaging which provides added protection for the finished parts, and very accurate part counts. We currently produce 8 million of these components annually for this client, delivering finished products on a Just-in-Time (JIT) delivery schedule. Shipments include all applicable Material Certification and Certificates of Conformance. Quality control was maintained through a vision system as well as an optical comparator. Along with a batch sample retention system, we maintained a zero defect to the customer. To learn more about this custom progressive die stamping project, please see table below or contact us directly.

| Precision Progressive Die Stamping Capabilities Applied/Processes | Primary: Die Design & Build Progressive Die Stamping Secondary: Special Packaging • Reel-to-Reel Special Process • Automatic Packaging for Accurate Counts and Protection of Parts |

| Equipment Used to Manufacture Part | 4 Post High Speed 30 Ton Bruderer |

| Overall Part Dimensions | .162”x .694” (Excluding Carrier) |

| Tightest Tolerances | ±.003” |

| Material Used | .016” Thick CA521 Phosphor Bronze |

| In process testing/inspection performed | Vision System Production Inspection Plan Optical Comparator First Article Inspection Race Track for Critical Dimensions Batch Sample Retention Sensored for Die Protection Raw Material Certification Certificate of Conformance (COC) |

| Industry for Use | Automotive |

| Volume | 8,000,000 Annually |

| Delivery/Turnaround Time | Just In Time (JIT) |

| Delivery Location | USA |

| Standards Met/Directives Met | ISO 9001 QMI-SAI Global ANAB RoHS DFARS |

REACH ASTM MIL-SPEC Dodd-Frank (Conflict Materials Act) |

| Product Name | Terminal Bulb Socket |

| File Format | SolidWorks |