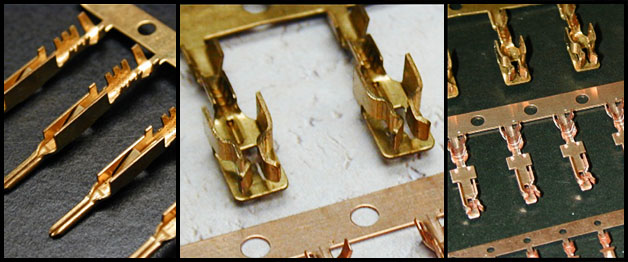

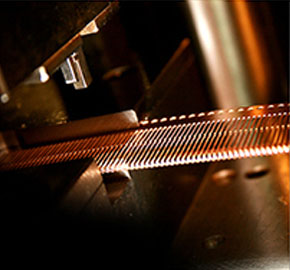

Gerhart Stamping’s high speed stamping department has a tonnage range from 22 to 60 tons utilizing state of the art Bruderer presses. We stamp copper based, ferrous, exotic and high performance metals at thicknesses between .001” to .060” thick with speeds ranging from 100 to 1500 SPM. Featuring Cognex advanced vision systems, our stamping department establishes 100% continuous inspection of critical dimensions and where tight tolerances are required. We offer Statistical Process Control (SPC) for customers as well. Due to the growing need for shorter lead times and JIT shipments, we compliment our EDM department with a modern grinding facility. This assures that our tooling or customer supplied tooling, is always maintained and ready to run. With both reel-to reel and loose parts capability along with pre or post plating options, we are sure to be the right choice for your stamping needs. Gerhart Stamping, Inc is an ISO 9001 Certified Company. For more information about our Stamping Services, please see table below or contact us directly.

| General Capabilities | Custom Stamping High Speed Stamping Progressive Stamping Tight Tolerance Stamping Strip Stamping Multi-Thickness Strip Stamping Bandolier Stamping Reel-to-Reel Stamping |

Loose Piece Stamping Single-Out Stamping Multi-Out Stamping Micro-Miniature Parts Miniature Parts Small Parts Medium Parts |

| Industry Focus | Automotive Consumer Electronics Computer Military Appliance Medical |

Aerospace Telecommunications Industrial Agriculture and many more… |

| Stamping Products | Connectivity Contacts Connectors Wire Crimp Connectors Electronic Connectors High Temp Contacts High Temp Connectors Springs for Seals Calculator Buttons Box Contacts Parts for Insert Molded Components Compliant Pins |

Bellows Contacts Cantilever Contacts Press Fit Contacts Dip Solder Contacts Edgecard Contacts Sensor Components Printed Circuit Board Contacts Surface Mount Pins Switch Contacts Battery Contacts Terminals Header Pins and many more… |

| Stamping Alloys | Phosphor Bronze Copper Beryllium Copper Brass Nickel Nickel –Silver Beryllium Nickel Spinodal (a.k.a. Pfinodal) Bronze Stainless Steel Zirconium Copper |

High Performance Alloys White Metal Exotic Metal Ferrous Inlay Mylar Bi-Metal Skived Pre-Plated (All Over) Pre-Plated Selective (Gold Stripe) and many more… |

| Tempers | Annealed (H00) to Extra Spring Hard (H10) |

| Stamping Alloy Sources | Diehl Metal (The Miller Company) Olin Brass Heyco Metals Eagle Brass |

Materian (Brush Wellman) Fisk Alloys Ametek E. Jordan Brookes Company |

| Production Volume | Low Volume High Volume Large Scale Production |

Blanket Orders Contract Orders |

| Shipments and Deliveries | JIT (Just in Time) Deliveries Global Shipments Split Shipments |

Expedited Shipments Custom Packaging |

| Stamping Features | P/A Industries Fully Automatic Material Feeding Equipment P/A Industries Fully Automatic Take Up Reeling Equipment Cognex In-Line Vision Inspection Systems Die Crash Protective Systems (Prevents Job Delays) Digital Counting for Accuracy |

| Press Type | Bruderer |

| Press Rating | 22 to 60 Tons |

| Press speed | 100 to 1500 SPM (Strokes Per Minute) |

| Max. Press Bed Length | 35.75” in. 908.05 mm |

| Max. Press Bed Width | 25.59” in. 649.98 mm |

| Max. Part Width | 3.00” in. 76.2 mm |

| Part Thickness Minimum | .001” in. .0254 mm |

| Part Thickness Max. | .060 in 1.524 mm |

| Part Tolerance | +/- .0005” in. (Coining) .0127 mm +/- .001” in. (Geometry Cuts) .0254 mm +/- .003” in. (Forms) .0762 mm +/- ½ Degree (Angles) |

| Additional Services | Plating Service (Turn Key Product) Lot Heat Treating Lot Part Tumbling Video Measuring Systems SPC Reports (Statistical Process Control) FAI Reports (First Article Inspection) COC (Certificate of Compliance) Raw Material Certification Traceability Engineering Support Customer Support |

| Industry Standards | ISO 9001 QMI-SAI Global ANAB RoHS DFARS |

REACH ASTM MIL-SPEC Dodd-Frank (Conflict Materials Act) |

| File Formats | AutoCAD (DWG) SolidWorks DXF IGES |

JPG GIF BMP Unigraphics (PRT) |